All-in-one energy storage system built-in 100KW module PCS is designed for commercial and industrial scenarios.

Item No :

PowerOn D4Order(MOQ) :

100 pieces. Accept one piece at sample price.Payment :

Paypal / TT / Western UnionProduct Origin :

ChinaColor :

WhiteShipping Port :

Ningbo, Shanghai, ShenzhenLead Time :

25 - 45 daysALL-IN-ONE 215-260 KWH ESS BUILT-IN 100KW MODULE PCS INSIDE A CABINET

The liquid-cooling container storage system is mainly used in large-scale renewable energy generation and consumption, power grid peak regulation and frequency modulation, emergency backup, delayed distribution network upgrade, distributed power generation and micro-grid systems. It always applied in commercial and industry scenarios. Modular structure design is adopted, the battery capacity is optional, and the scalability is strong, which can meet the power and energy requirements of different scenarios.

Safe and reliable: Liquid-cooling heat dissipation design, cell temperature difference <3 degrees Celsius, intelligent thermal management strategy, energy consumption reduced by 20%, comprehensive system life increased by 30%.

Highly integrated: IP54 protection level, C4 anti-corrosion level design, battery-level active + passive fire protection design, independent fire protection system, and cloud AI intelligent inspection.

High-rate discharge: Modular design, compatible with 1000V/1500V systems, reducing the floor space by 40%, transporting and installing the entire machine, and reducing EPC costs.

The battery pack uses LFP batteries and is paired with selfdeveloped BMS. One battery cabinet consisting of 10 packs with integrated air cooling and fire protection to ensure system safety, while the system can be freely expanded according to project requirements.

|

•

|

• Backup PowerPrime ESS provides emergency power in milliseconds during grid off |

• Peak ShavingPrime ESS provides additional electricity if a peak load occurs |

• Market ParticipationPrime ESS acts as virtual plant to participate in electricity market trades |

• Time of Use

Charge and discharge prime ESS at different electricity prices time

• Peak Shaving

Prime ESS provides additional electricity if a peak load occurs

• Backup Power

Prime ESS provides emergency power in milliseconds during grid off

• Market Participation

Prime ESS acts as virtual plant to participate in electricity market trades

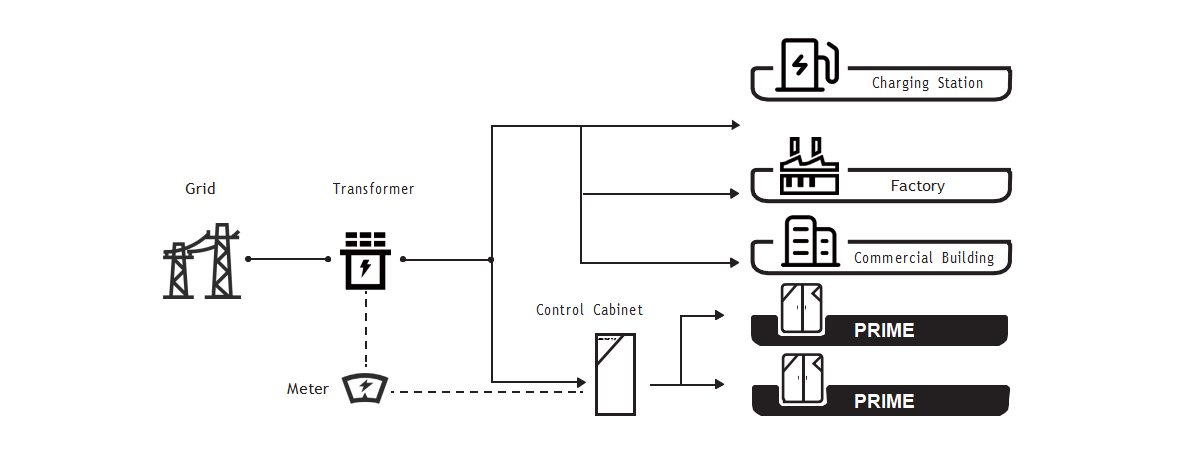

Electronic Architecture

Prime ess is easy to connect and flexible to deploy. Each prime system is connected to a cluster control cabinet, which is then connected to a low voltage distribution cabinet under the transformer. The cluster control cabinet communicates in real time with the prime system and the smart meter on the transformer side to obtain their energy status. The system automatically discharges during peak hours or high loads, thereby reducing the use of the high-cost grid. Low voltage side access allows the saved power to reach the load without going through the transformer, avoiding the loss of transformer voltage conversion.

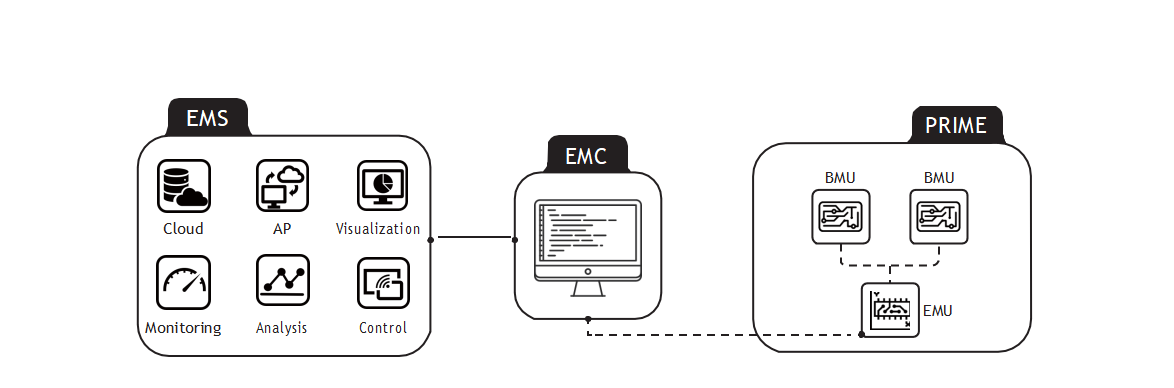

Control System

TMR Platform provides a rich visual interface that allows users to view equipment operating status, load power and revenue in real time.

The EMC system willdy namically allocate the output power of each Prime device to reasonably allocate Prime system working time.

Local EMU system integrates device control,system protection, battery management to ensure the perfect operation of the system.

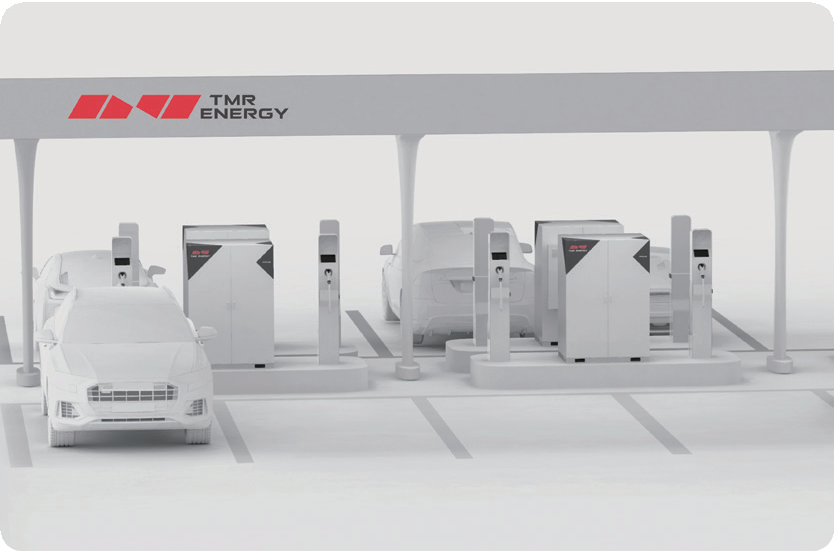

Charging Station

By deploying prime in between of each charger could avoid expensive grid connection expansion, since prime regulates the load peaks to protests against overload while save electrical bills.

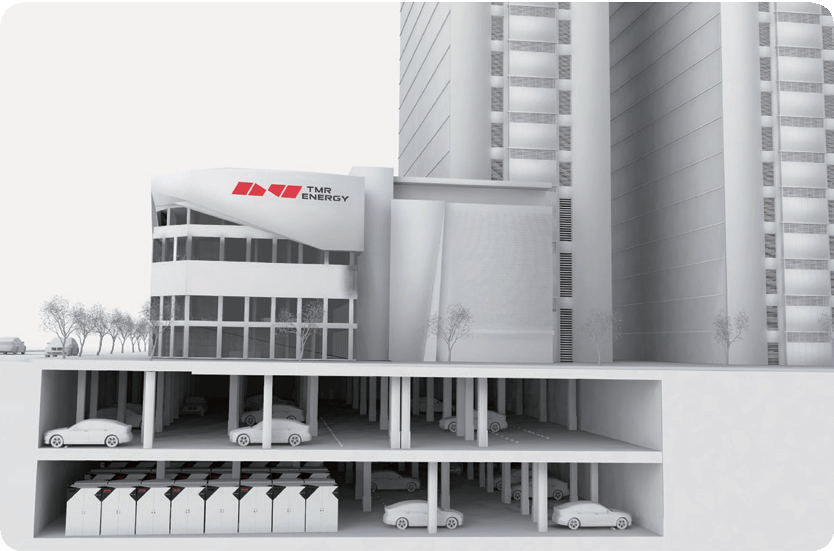

Commercial Building

Commercial buildings have high electricity needs with predictable time-based peaks, energy storage can significantly lower electricity costs. However, the space of commercial buildings is limited.

Airport

Prime replaces diesel generators as auxiliary power unit (APU) to provide power and air conditioning for the aircraft while parking at the airport.

Factory

Prime embedded multilayer artificial neural network is able to forecast in load changing in advance, adjust control algorithms instantaneous- ly to reduce electrical costs.

| Model | PowerON D4 | PowerON D4-P | PowerON D4-M |

| Rated Capacity(Ah) | 280 | 280 | 314 |

| DC voltage(kWh) | 215.04 | 232.96 | 261.248 |

| Usable power@90%DOD(kWh) | ≥185 | ≥198 | ≥220 |

| Usable power@100%DOD(kWh) | ≥205 | ≥220 | ≥245 |

| Rated Voltage(V) | 768 | 832 | |

| Battery Group Mode | 1P240s | 1P260s | |

| Working Voltage Range(V) | 672~864 | 728~936 | |

| Rated Charge Current(A) | 140 | 140 | 160 |

| Max. Charge Current(A) | 250@10s | ||

| Rated Discharge Current(A) | 140 | 140 | 160 |

| Max. Discharge Current(A) | 250@10s | ||

| Rated AC Output Power(kW) | 100 | 125 | |

| Wiring Method | Three-phase Four-wire | ||

| AC Overload Capacity | *1.1 | ||

| Allowed Grid Voltage(V) | 400(-15%~15%) | ||

| Allowed Grid Frequency(V) | 50(-2.5~2.5) | ||

| Power Factor | 0.99/-1~1 | ||

| Noise Level(dB) | <80 | ||

| Protection Degree | IP54 | ||

| Fire Protection Configuration | Perfluorohexanone | ||

| Max. Altitude(m) | 3000 (derate over 2000) | ||

| Communication Port | RS 485, Ethernet, CAN | ||

| Communication Protocol | Modbus TCP/RTU, CAN2.0 | ||

| Operating Temperature(℃) | 0~55(charging) | ||

| -20~55(discharge) | |||

| Weight(kg) | ≤3000 | ||

| Humidity(Rh) | ≤90% | ||

| Storage Temperature(℃) | -20~45 | ||

| 0~35 | |||

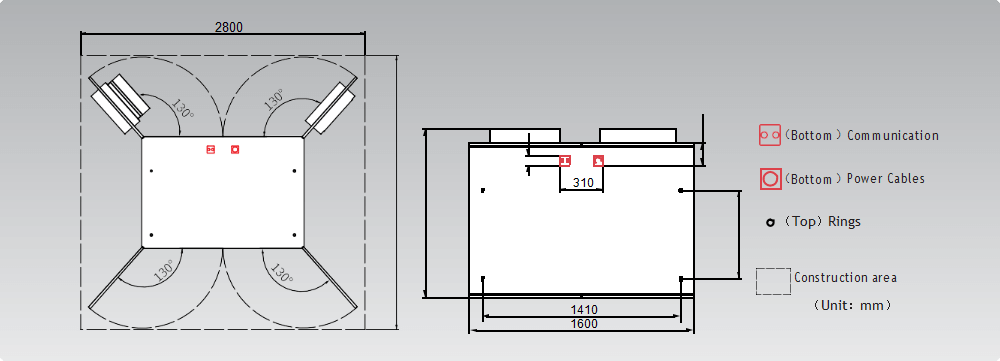

| Dimension(W/D/H,mm) | 1400×1500×2200 | ||

| Application Altitude(m) | ≤2000 | ||

| Certification | GB/T 36276;IEC62619;IEC 62477;IEC 61000 | ||

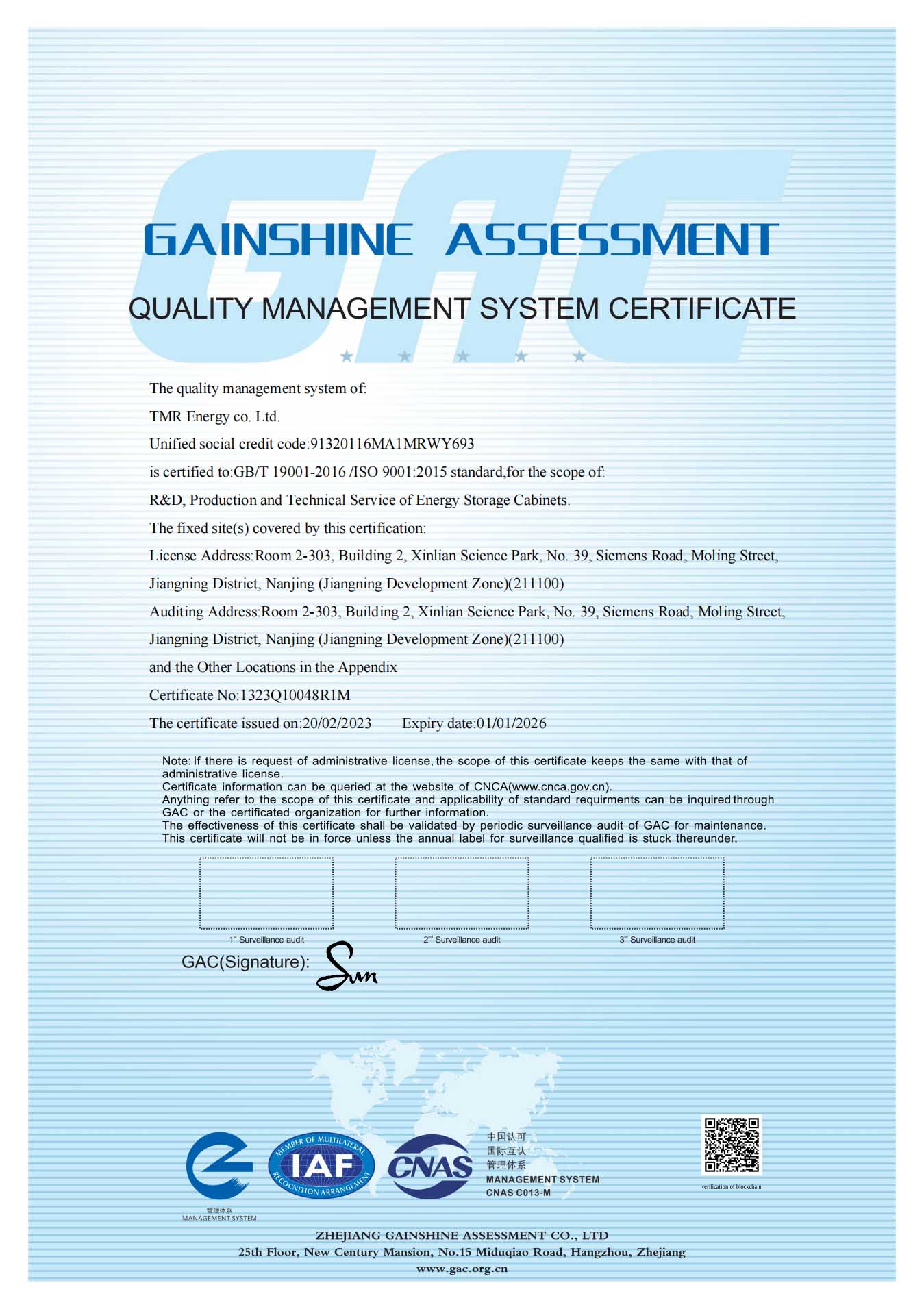

Quality management system certificate

Environment Management System Certificate